Can automobile exhaust pipes be welded by laser welding machine

Addtime:2021-11-10 Browse times:1284

With the continuous maturity of today's laser application technology, the application and utilization of laser are becoming more and more convenient. It is widely used in many fields such as electronic consumer goods, packaging, shipbuilding, aerospace and automobile manufacturing. The excellent performance advantages and high-precision production and processing characteristics have given us a qualitative leap in product quality, It has created more comfortable products and services for people's life. Nowadays, laser welding technology has been widely used in today's automobile manufacturing field, introducing new vitality to today's automobile production and processing, and has become an important method of today's automobile production and processing. In today's automobile high-voltage relay, filter, torque sensor, turbocharger, oil rail, cylinder pad, spark plug, block motor stator, seat adjustment screw Airbag is widely used in welding process. Different parts of the car need different laser welding equipment. Today, let's share whether the automobile exhaust pipe can be welded with a laser welding machine?

Can automobile exhaust pipes be welded by laser welding machine

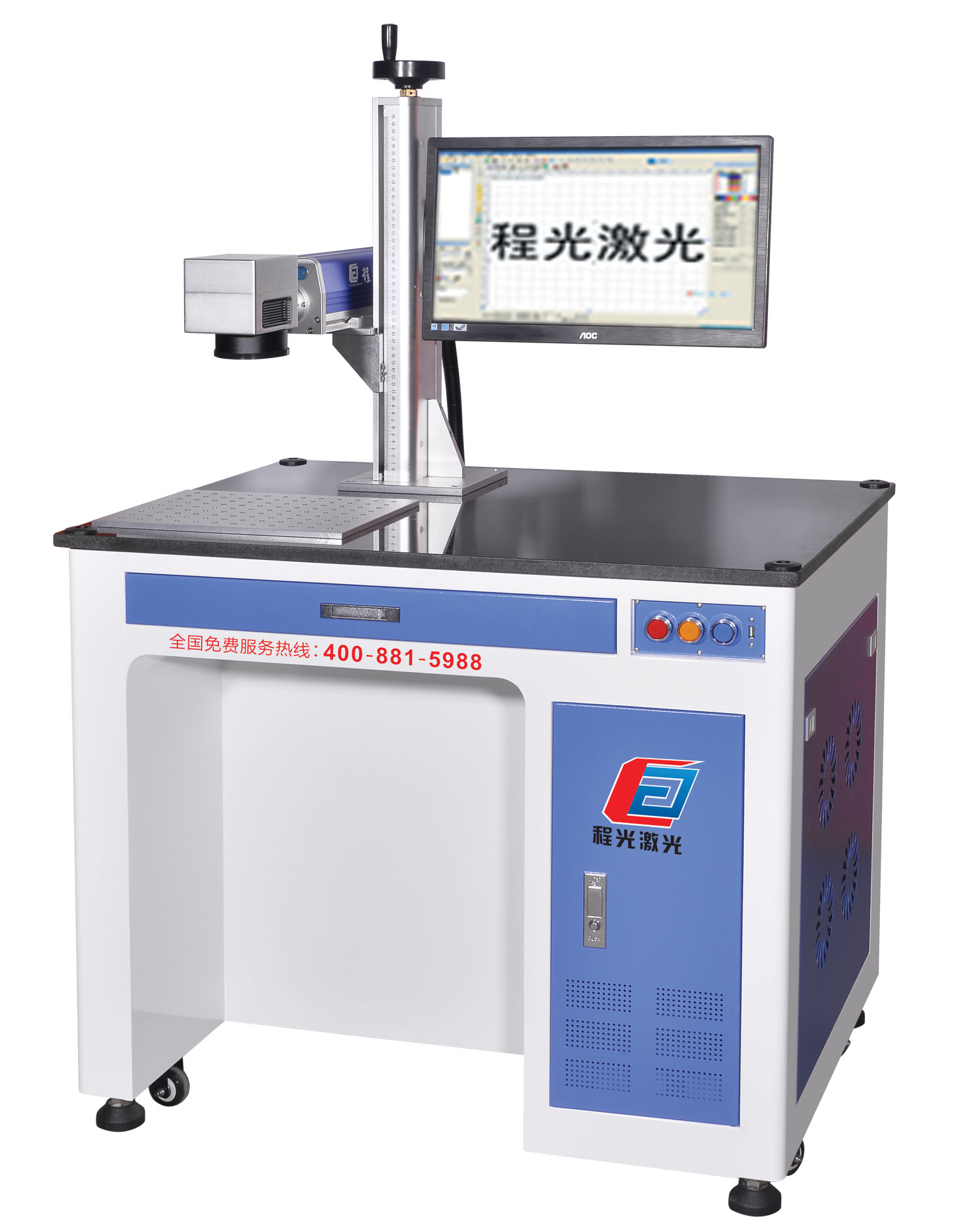

Naturally, it is possible, but the cost is higher than that of argon arc welding. The laser welding machine for automobile exhaust pipe uses high-energy pulse laser to weld objects. The machine has small volume, beautiful overall appearance, high-performance transmission optical fiber and high cost performance.

Auto parts laser welding machine is mainly used for auto parts laser spot welding, seam welding and air tightness welding. It has the advantages of small heat affected zone, high efficiency and low processing cost. It can weld small and precise geometric areas, with excellent repair effect, fast welding repair speed, no color difference or small color difference after welding. It can also deposit, seal and repair defects such as wear, scratch, crack, defect deformation, reduced hardness and sand holes on metal workpieces. It is easy to use. After repair, the matrix is not deformed, annealed, undercut and residual stress, and the metal structure state is not changed. High repair precision, coating thickness from a few microns to a few millimeters. According to the linkage control of external signals, it is convenient to carry out automatic / semi-automatic industrial production. Automobile manufacturing industry is a large-scale industry using laser welding technology in current industrial production. The flexibility of optical fiber laser welding machine can achieve the production and processing of various automobile materials, reduce automobile production cost and improve overall performance.

What is used to weld the exhaust pipe

Naturally, it is laser welding of automobile exhaust pipe, with beautiful overall appearance and high efficiency. The exhaust pipe shall be welded by gas shielded welding machine or argon arc welding. If it is ultra-thin, it shall be welded by cold arc welding machine, which has different advantages. Generally, it needs to produce welding efficiency, it shall be gas shielded welding machine. If it needs to be more detailed and beautiful, it shall be argon arc welding. If the living accuracy needs to be particularly high and the parent material is particularly thin, it shall be cold arc welding machine.